Industrial Filter Media Catalyst Carrier Alumina Ball 23% Inert Alimina Ceramic Ball

Overview Product Description Inert Porcelain Ball 23% Support Media Al2O3 Alumina Ceramic BallsProducts introduction: 23

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | KS-CB01 |

| Acid Resistance | 99.8% |

| Keywords | Ceramic Ball |

| Al2O3 | 23% |

| Sio2 | 70-77% |

| Moh′s Hardness Scale | 6.5 |

| Content | 23% |

| Color | Grey |

| Size | 3mm, 6mm, 13mm, 19mm |

| Customized | Customized |

| Processing Type | Rolling Type |

| Transport Package | Plastic Bag, Super Sack, Steel Drum |

| Specification | 6mm-75mm |

| Trademark | KSOURCEEP |

| Origin | Pingxiang Jiangxi, China |

| HS Code | 6909190000 |

| Production Capacity | 300-500 Ton/Per Month |

Product Description

Product Description

Inert Porcelain Ball 23% Support Media Al2O3 Alumina Ceramic BallsProducts introduction:

23%AL2O3 Inert Alumina Ceramic Ball (Catalyst Support Media) are the most widely used as Catalyst Support Media in the world wide because of their excellent consistence and reliability. It produced by very high quality chemical-porcelain clay materials, which has quite excellent stability, high mechanical strength and resistance to thermal shock, This makes them all ideal choice for support of all types of catalyst.It's widely used in petroleum, chemical, fertilizer, gas and environmental protection industries, as a catalyst in the reactor to cover support material and tower packing.It has a high temperature and high pressure resistance, bibulous rate is low, the characteristics of the chemical performance is stable.Can withstand the erosion of acid, alkali and other organic solvents, and can endure in the production process of temperature changes.Its main function is to increase gas or liquid distribution points, support and protection intensity is not high activity of the catalyst.

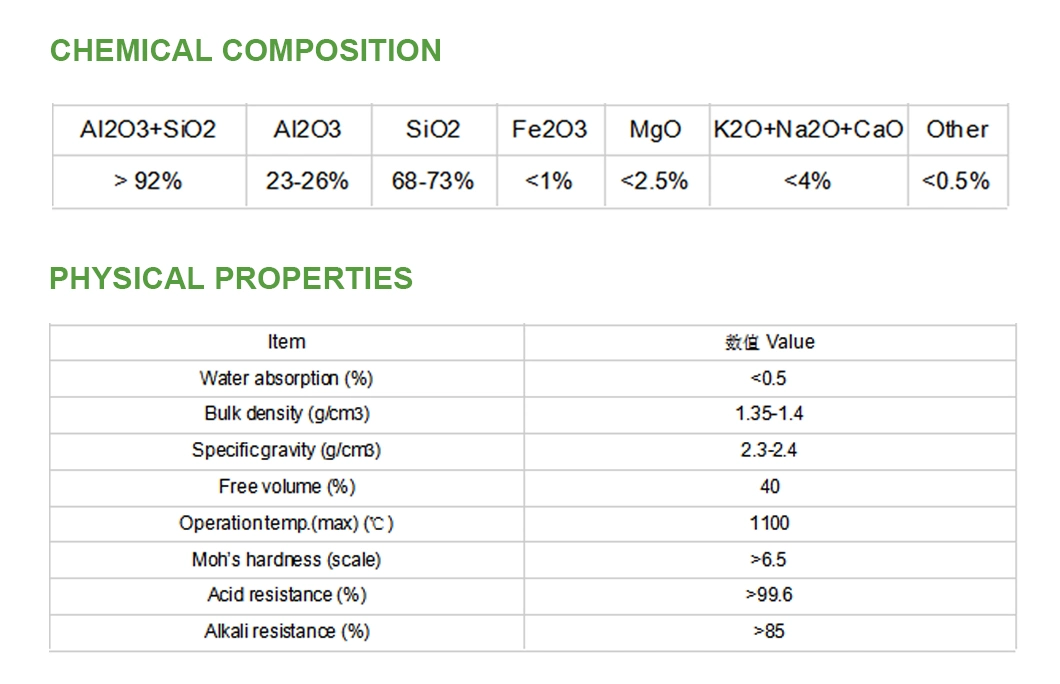

Chemical composition

| Al2O3+SiO2 | Al2O3 | SiO2 | Fe2O3 | MgO | K2O+Na2O+CaO | Other |

| > 92% | 23% | 68-73% | <1% | <2.5% | <4% | <0.5% |

| Item | Value |

| Water absorption (%) | <0.5 |

| Bulk density (g/cm3) | 1.38-1.4 |

| Specific gravity (g/cm3) | 2.3-2.4 |

| Free volume (%) | 40 |

| Operation temp.(max) (ºC) | 1100 |

| Moh's hardness (scale) | >6.5 |

| Acid resistance (%) | >99.6 |

| Alkali resistance (%) | >85 |

| Size | Crush strength | |

| Kgf/particle | KN/particle | |

| 1/8''(3mm) | >20 | >0.20 |

| 1/4''(6mm) | >50 | >0.50 |

| 3/8''(10mm) | >85 | >0.85 |

| 1/2''(13mm) | >180 | >1.80 |

| 3/4''(19mm) | >430 | >4.30 |

| 1''(25mm) | >620 | >6.20 |

| 1-1/2''(38mm) | >880 | >8.80 |

| 2''(50mm) | >1200 | >12.0 |

Detailed Photos

Packaging & Shipping